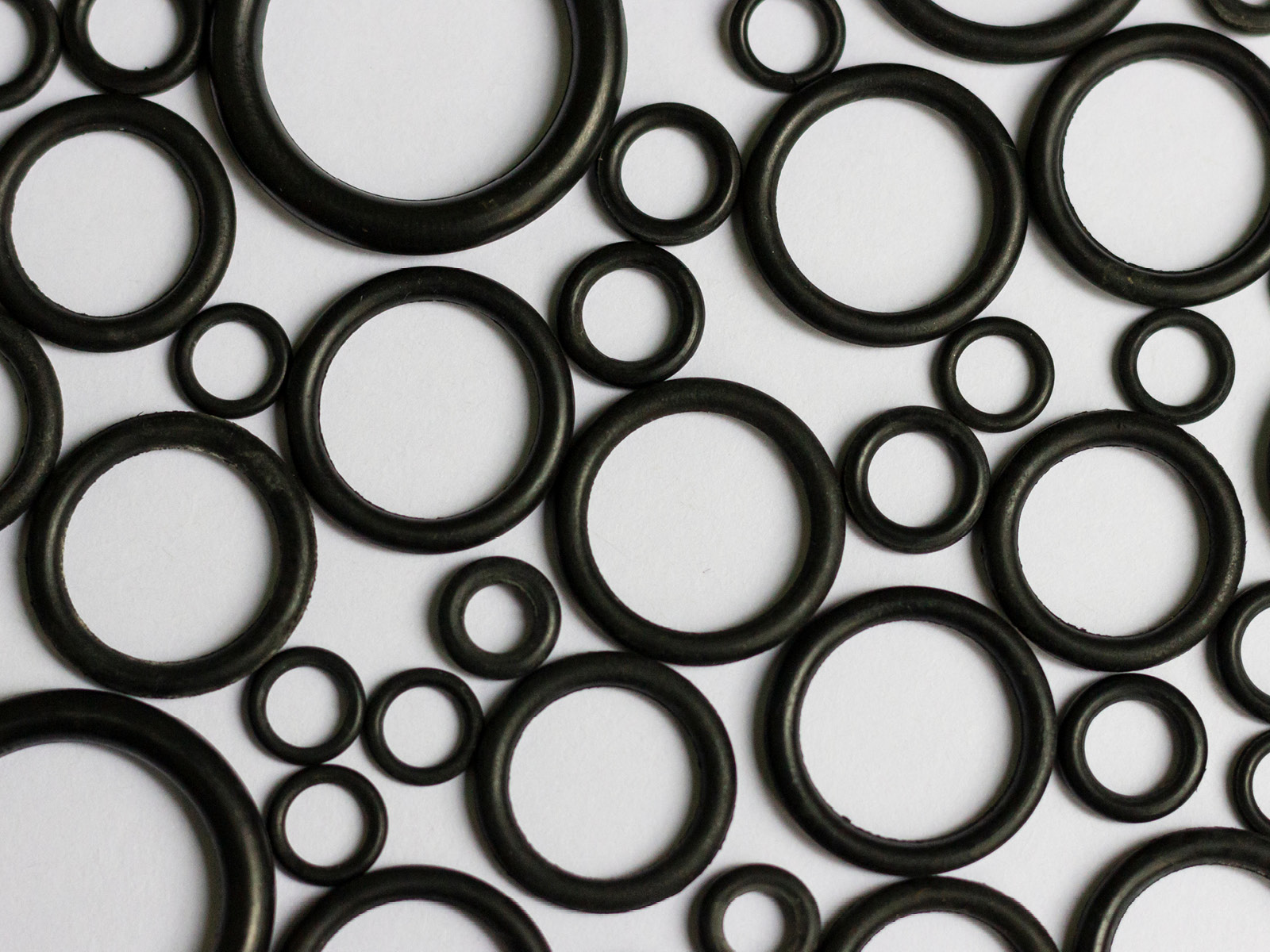

A Year of Growth and Gratitude at Marco Rubber & Plastics

Reflecting on a Milestone Year 2025 was a big year for Marco Rubber & Plastics. We welcomed new leadership, added Colonial Seal Company to the Marco Group, expanded our in-stock inventory, and implemented meaningful price reductions across key materials. Each change strengthened how we serve our customers, allowing us to offer faster quotes, more availability, […]